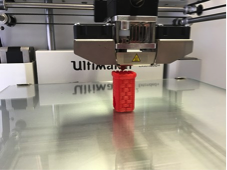

Is 3D Printing The Future of Medical Device Manufacturing?

A constant wave of new technology washes over us all. Whether we like it or not, change is inevitable and ongoing. That certainly applies to manufacturing. A prime example is the changes the music industry has undergone in the past twenty years. Their business model, once dependent the manufacture and sale of CD’s, had to adjust to a new world of digital downloads and live concerts as their primary revenue stream.

In the world of manufacturing, 3D printing is certainly shaking things up with new possibilities and applications previously confined to the more traditional manufacturing processes. A recent article in plasticstoday.com highlighted some of the changes this relatively new technology is bringing to the world of medical device manufacturing. As the article mentioned, “one of the strengths of 3D printing lies in the ability to globalize data and manufacturing simply by sharing a file.” It involves a “democratization” of manufacturing that could lead to a future of DIY medical devices for fun and profit.

3D printing for MedTech devices does have limitations.

Limitations do exist in use of 3D printing technology for production of medical devices. They lie mainly in the area of precision and performance, falling short of the quality found using the more traditional manufacturing method of injection molding. Also, associated cost and scalability are issues.

Still, there are applications where 3D printing is now being used.

Examples of current applications for 3D are patient-specific prosthetic devices and high-resolution anatomical models that surgeons can use to prepare for especially difficult procedures.

Implants are another area of opportunity.

“Say part of your pelvis or jaw needs to be repaired or replaced; you can produce a custom part using the scanned patient data, and the materials, which typically have a rougher finish, actually work really well for bio-integration.” And, 3D printing could make medical devices more affordable by selling designs and files (digital) instead of the actual product.

Manufacturing has always been focused on faster, cheaper machines that can achieve economies of scale. More and more, 3D printing represents a digital solution for manufacturing when going from prototype to scale in an easy, cost-effective way.

Contact us today at Key Corporate Services to find your dream job in Manufacturing & Engineering.